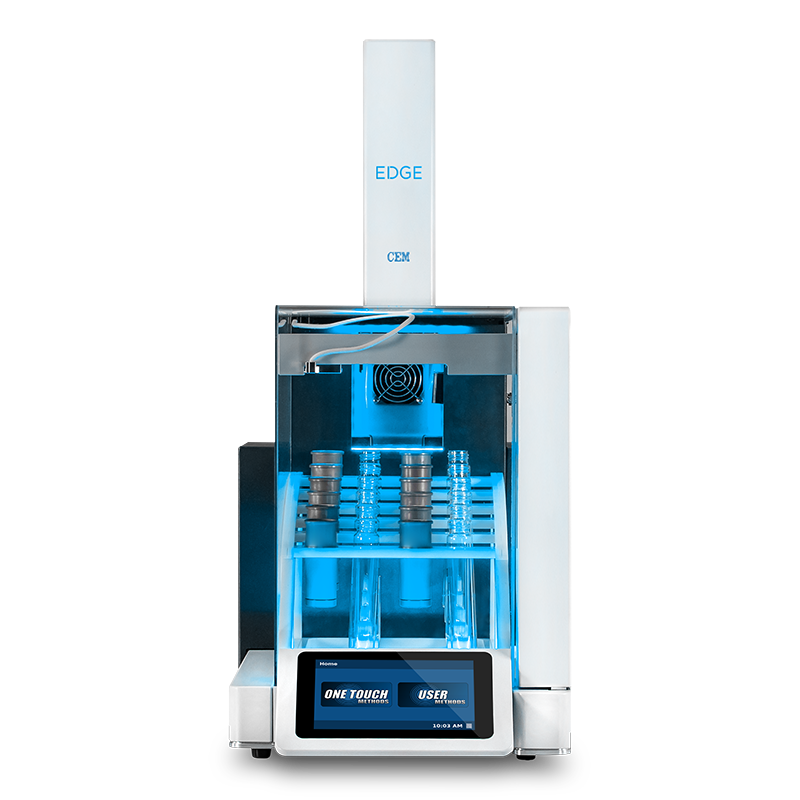

Geautomatiseerd oplosmiddelextractiesysteem

EPA-methode 3545A

De EDGE is een geautomatiseerd oplosmiddelextractiesysteem dat voldoet aan de vereisten van de Amerikaanse EPA-methode 3545A. Dankzij Q-Cup-technologie wordt Energized Dispersive Extraction eenvoudig en snel toepasbaar voor alle toepassingen.

Extraheer een breed scala aan monstertypes en -groottes minstens drie keer sneller dan met traditionele vloeistofextractors onder druk, inclusief filteren, koelen en wassen. Met het EDGE-systeem extraheert u moeiteloos semi-vluchtige organische stoffen uit bodem, vetten uit voedingsmiddelen, ftalaten uit kunststoffen en nog veel meer.

Eenvoudig geautomatiseerd extractieproces:

1. Monster laden

De automatische monstervoorbereiding laadt de Q-Cup in de extractiekamer. Vervolgens zorgt de drukdop voor een betrouwbare afdichting onder druk aan de bovenkant van de Q-Cup.

2. De matrix toevoegen

Eerst wordt via de onderkant oplosmiddel toegevoegd om de ruimte tussen de extractiekamer en de Q-Cup te vullen, wat de warmteoverdracht mogelijk maakt. Daarna wordt oplosmiddel vanaf de bovenkant van de Q-Cup toegevoegd om het monster te bevochtigen.

Wanneer de wanden van de kamer opwarmen, neemt de druk in de oplosmiddelopening toe. Dit overwint de druk in de Q-Cup, waardoor het oplosmiddel gelijkmatig in het monster wordt gedispergeerd.

3. Het extract verzamelen

Zodra het monster de gewenste temperatuur heeft bereikt, stroomt het oplosmiddel door de Q-Disc, langs de koelspiraal en uiteindelijk in een opvangflesje.

Flexibel geautomatiseerd oplosmiddelextractiesysteem

Betere resultaten met één instrument

- Dispersieve vastefase-extractie

- Vloeistofextractie onder druk

- Ondersteunde vloeistofextractie

- Vloeistof-vloeistofextractie

Met EDGE zijn meerdere systemen voor verschillende monsters overbodig. Dankzij de Q-cup technologie verwerkt EDGE alle extracties en levert het een deeltjesvrije oplossing die direct klaar is voor analyse, ongeacht de gebruikte techniek.

Als geautomatiseerd oplosmiddelextractiesysteem vereenvoudigt EDGE workflows door meerdere extractietechnieken in één compact instrument te integreren.

Het compacte formaat is een groot voordeel!

Edge PFAS

Na meerdere spoelingen is de reinheid van de EDGE en de achtergrond van de S1 Q-Disc®, Q-Matrix Hydra™ en Q-Cup® grondig getest. De resultaten tonen aan dat deze onderdelen een PFAS-vrije achtergrond bieden. Daardoor is de EDGE de ideale oplossing voor laboratoria die PFAS-extracties willen automatiseren zonder risico op ongewenste contaminatie.

Lees onze blogposts: