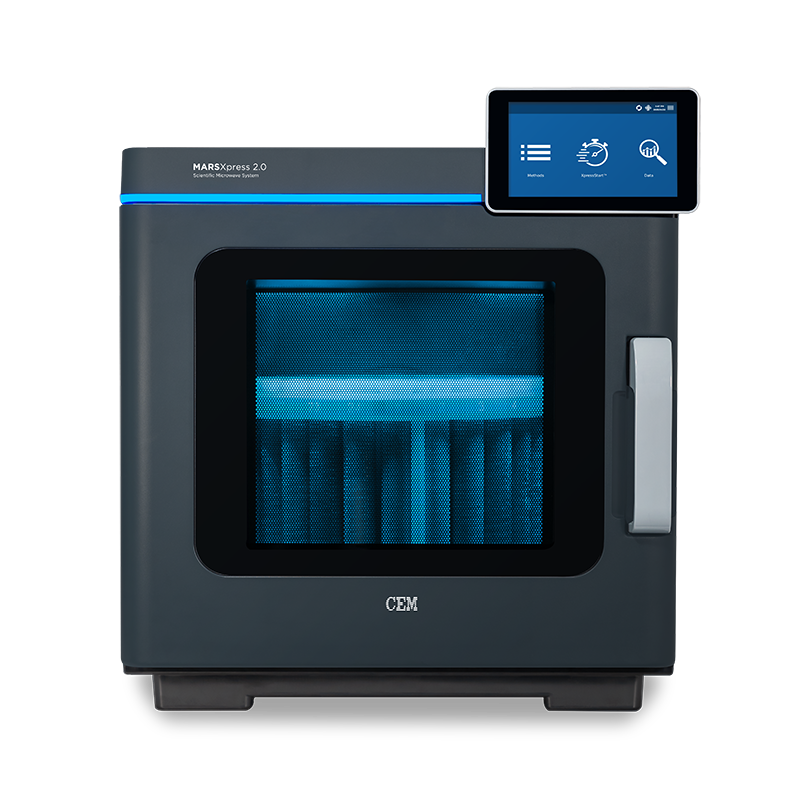

Scientific microwave system

Designed and built by the leader in sample preparation, the MARSXpress 2.0™ digestion system delivers simplicity, flexibility, and accessibility for every laboratory. This scientific microwave system is the most cost-effective solution available to handle all your sample preparation needs.

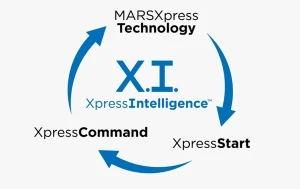

XpressIntelligence

Advanced XpressIntelligence™ (X.I.) combines MARSXpress™ Technology, XpressStart™, and XpressCommand™ into one powerful system. This includes the industry-leading MARSXpress vessel family, intuitive one-touch startup methods, and convenient voice-command capabilities.

Effortless programming and easy vessel assembly

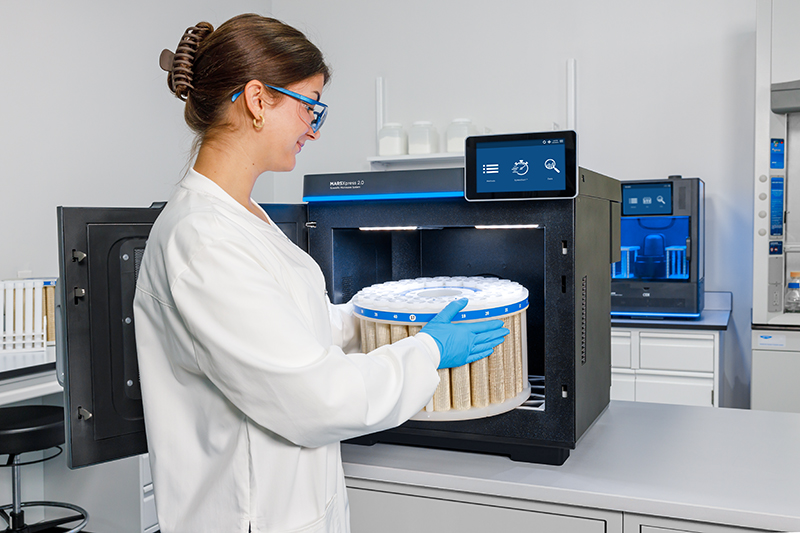

XpressStart methods make starting a digestion effortless: simply select the desired temperature and press start. It’s that easy! The system takes care of all other parameters automatically. From fast single-sample screening to digest up to 40 samples at once, the MARSXpress 2.0 handles it all. The system delivers the optimal amount of microwave power, ramp time, and hold time to safely digest each sample, every time.

A simple three-piece assembly makes the world’s most popular vessel the clear choice for the MARSXpress 2.0. It meets high-throughput lab demands while complying with both USEPA and European Norm methods.

Batch up to 40 samples with this scientific microwave system

Whether you’re digesting a single rush sample, screening for optimal conditions, or digesting 40 samples in a batch. Simply load the vessels in the MARSXpress 2.0 and press start. The robust MARSXpress vessels come in size from 20 mL to 110 mL. This makes them suitable for a wide variety of sample volumes. From food samples to environmental samples and more, MARSXpress 2.0 will completely digest each one, readying them for ICP-MS or ICP-OES analysis.

Get information like never before with this scientific microwave system

Accurate temperature sensor

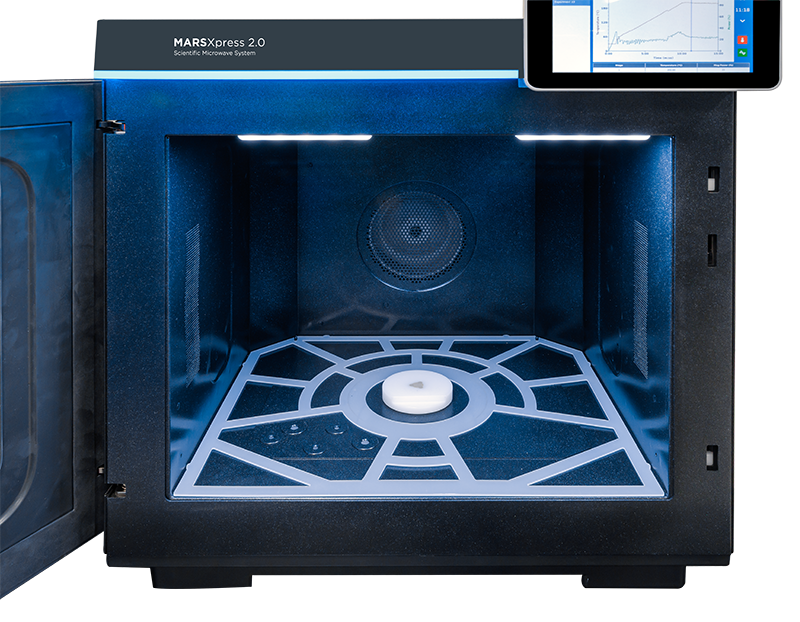

The MARSXpress 2.0 uses the most accurate temperature sensor available, iWave, even in this economical system. This contactless in-situ temperature sensor ensures accurate and reliable readings for every sample, regardless of its position in the cavity or the total number of samples in the batch. Upon run completion of the run, the MARSXpress 2.0 automatically cools the samples to a predefined temperature, allowing safe removal in a timely manner.

The differential pressure sensor ensures proper airflow for vapor evacuation. It continuously monitors airflow before, during, and after the run to effectively remove all harmful vapors from the MARSXpress 2.0 cavity. If airflow conditions fall below required thresholds, the system will immediately alert the user.