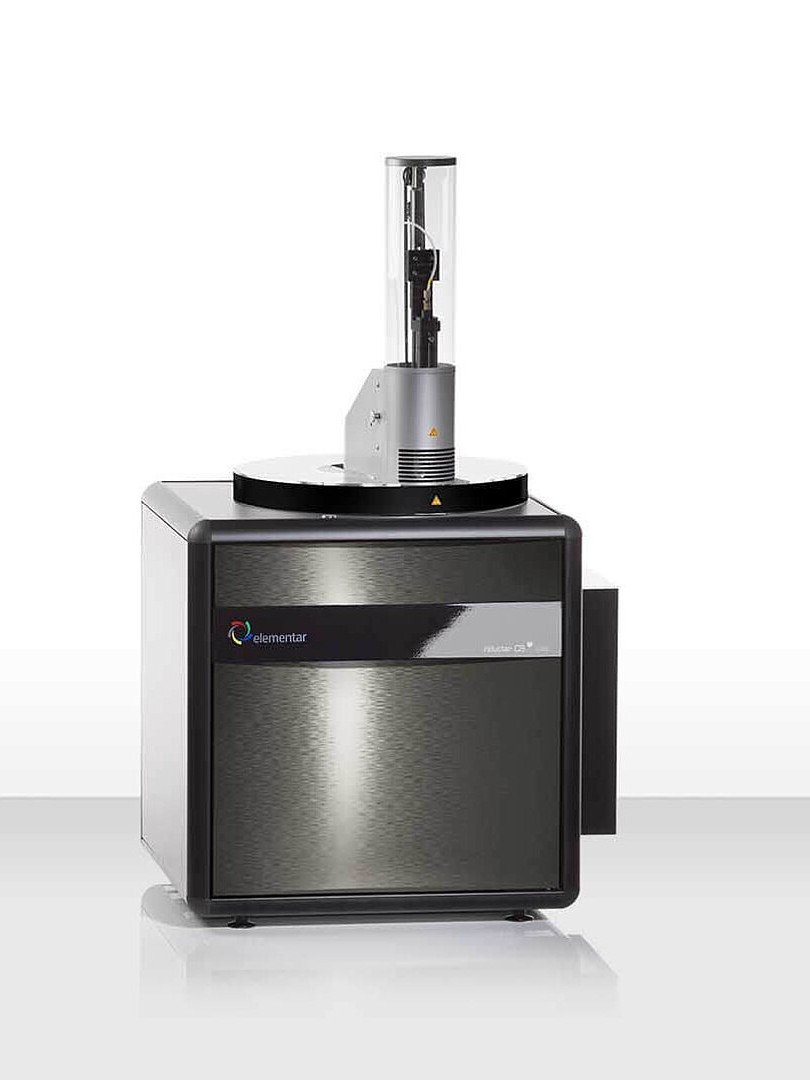

Advanced carbon and sulfur analysis of inorganic materials

This high-precision sulfur and carbon analyzer is designed for metallic or ceramic materials and incorporates state-of-the-art technologies. In addition, it features a long-life solid-state high-frequency induction furnace capable of reaching sample temperatures of up to 2000 °C. Furthermore, an optional camera allows the operator to observe gas release in real time.

For element detection, this sulfur and carbon analyzer utilizes advanced technologies with wide-range IR detectors for both carbon and sulfur analysis. are both analyzed by wide-range IR detectors, which are capable to detect the whole concentration range. These detectors can cover the entire concentration range, making it possible to accurately detect impurities in the ppm range as well as higher concentrations, even up to several percentages by weight.

Specifications:

Measuring method

High-temperature-combustion in oxygen atmosphere at up to 2000 °C, followed by purification of the analytical gas flow and subsequent gas analysis. CS-analysis is done according to ISO 15350, ASTM E1019 and further international standards.

Easy sample preparation and handling

Without any special sample preparation, all kinds of solid samples are weighed into ceramic sample containers (sample mass up to 1 g).

Clean and safe analysis

The innovative crucible design, together with top-down oxygen gas stream, minimizes any dust inside the system. Furthermore spattering of sample melt is prevented, which assures a virtually unlimited lifetime of the combustion tube.

Large concentration range

From a few ppm up to 100 % or 60 mg carbon and 5 mg sulfur absolute.

Linear single/multipoint-calibration

The operator is guided through the calibration by an intuitive calibration assistant. The transparently calculated calibration is editable and storable. Furthermore, templates can be stored for future calibrations. Calibration is linear and stable for months.

Few operational requirements

1 m laboratory working space, one electrical connection and one operating gas are sufficient for long term operation.

Full automation

Automated and unattended operation is possible with the integrated 89 position autosampler and PC-control through Windows®. Furthermore, optional 21 CFR Part 11 compliant software is available.