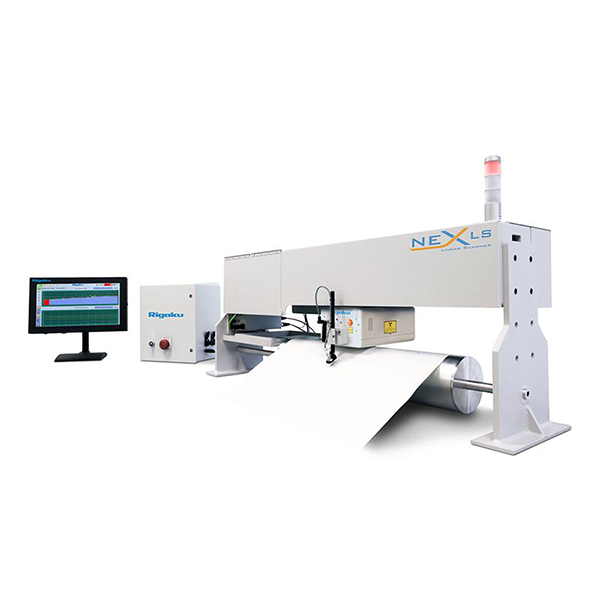

Sulfur process analyzer

The NEX XT is a sulfur process analyzer that provides total sulfur measurements ranging from 0.04 to 6 wt% in crude oil, bunker fuel, fuel oils, and other highly viscous hydrocarbons, including residuums.

It’s a versatile, compact, and durable X-ray transmission/absorption (XRT/XRA) process gauge, specifically designed for total sulfur analysis in refineries, pipelines, blending operations, bunkering terminals, and, other storage facilities.

The Rigaku NEX XT is an excellent on-line tool for sulfur analysis in petroleum streams, whether used for crude oil blending, monitoring, assaying, blending marine bunker fuels, or custody transfer. It is well-suited to meet the varying demands of the industry, helping you maximize profitability.

On-Line total sulfur gauge

NEX XT provides online, real-time X-ray transmission (XRT) measurements of sulfur, ranging from 400 parts-per-million (ppm) to 6 wt%, across various petroleum streams. It represents the next generation of process solutions for sulfur measurement in crude, bunker fuel, fuel oils, and other highly viscous hydrocarbons.

- Ideal for crude oil and refinery feedstock blending and monitoring

- Perfect for marine fuel blending and monitoring to meet IMO MARPOL regulations

- Quality monitoring of crude at remote collection and storage facilities

- Monitor high-temperature vacuum gas oils

X-ray Transmission / Absorption (XRT / XRA) Method

Many rely on X-ray Transmission (XRT) gauging to measure total sulfur (S) in heavy hydrocarbon process streams. The Rigaku NEX XT XRT process analyzer excels in demanding process environments, including pipeline switching, crude oil blending, and assaying and blending marine and bunker fuels. It provides continuous, reliable sulfur monitoring at pressures up to 100 bar (1480 psig) and temperatures up to 200°C with a custom configuration. The NEX XT operates as a standalone analyzer or integrate into a blending or plant-wide automation system to provide real-time, closed-loop control.

X-ray transmission gauging works by measuring how much a monochromatic X-ray beam, specifically at 21 keV, the energy characteristic of sulfur, is attenuated as it passes through a sample. In practice, a process stream passes through a flow cell where sulfur (S), in the hydrocarbon matrix, absorbs X-rays transmitted between an X-ray source and detector. The recorded X-ray intensity is inversely proportional to the sulfur concentration, thus higher sulfur levels result in lower X-ray transmission.