Enhanced elemental analysis for industrial quality control to advanced research applications

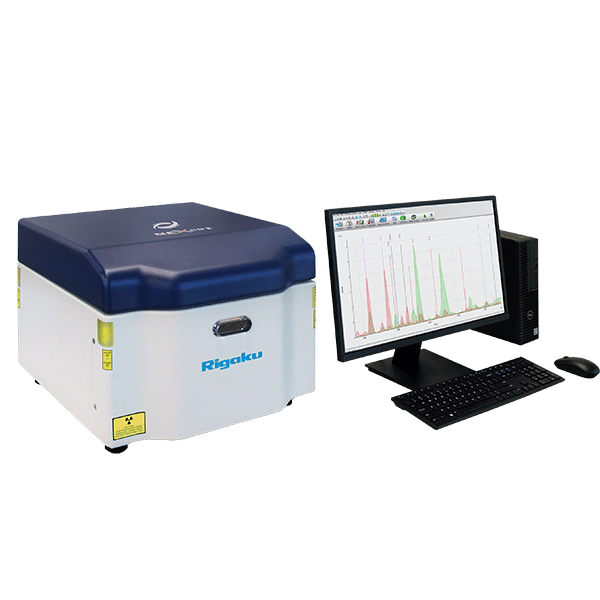

NEX CG II Series are advanced second-generation energy dispersive X-ray fluorescence (EDXRF) spectrometers designed for rapid qualitative and quantitative analysis of major and minor atomic elements. They handle a wide variety of sample types, including oils, liquids, solids, metals, polymers, powders, pastes, coatings, and thin films. They are ideal for measuring ultra-low to percent-level trace elements.

Cartesian geometry and polarization for trace-level sensitivity

NEX CG II Series X-ray fluorescence spectrometers address elemental analysis challenges with a close-coupled Cartesian Geometry optical kernel. This advanced design significantly enhances sensitivity by boosting the signal-to-noise ratio, resulting in superior elemental analysis performance.

Unlike conventional EDXRF spectrometers, NEX CG II Series uses an indirect excitation system with secondary targets instead of tube filters. This monochromatic and polarized excitation significantly improves detection limits, especially for elements in highly scattering matrices such as water, hydrocarbons, and biological materials. The full 90° Cartesian Geometry with secondary target excitation also eliminates background noise.

As a result, the NEX CG II Series spectrometers bring a new level of analytical sensitivity to XRF technology. They enable accurate measurement of ultra-low and trace element concentrations, even in complex or highly scattering sample types.

X-ray fluorescence spectrometers are well suited for the following applications:

- Agricultural soil and plant materials

- Finished animal feeds

- Waste oils

- Environmental monitoring

- Pharmaceuticals and cosmetics

- Catalysts

- Monitoring for toxic metals in aerosols on air filters

- Trace heavy metals and rare earth elements (REE)

- Other applications that require a high degree of sensitivity

Key advantages and features of X-ray fluorescence spectrometers

- Non-destructive elemental analysis for sodium (Na) to uranium (U)

- Quick elemental analyses of solids, liquids, powders, coatings, and thin films

- Indirect excitation for exceptionally low detection limits

- High-power X-ray tubes (50 kV 50 W or 65 kV 100 W)

- Large-area high-throughput silicon drift detector (SDD)

- Analysis in air, helium, or vacuum

- Powerful and easy-to-use QuantEZ software with multilingual user interface

- Advanced RPF-SQX Fundamental Parameters software featuring Scattering FP

- Rigaku Profile Fitting (RPF) advanced algorithm for peak deconvolution

- SureDI support for 21 CFR Part 11 compliance

- Various automatic sample changers accommodating up to 52 mm samples

- Low cost of ownership