Take your production to the next level with BRAVE B-Continuous

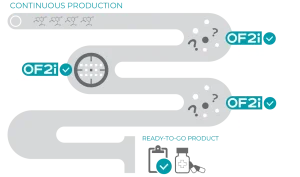

Revolutionize your production processes like never before! Not only will you save time and resources, but also reduce out-of-spec production and increase efficiency. BRAVE B-Continuous is the first true online PAT sensor enabling real-time, online nanoparticle characterization.

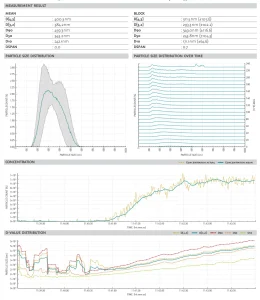

It continuously monitors particle size, size distribution, and concentration during production, delivering data directly to your network. Thanks to BRAVE B-Continuous, the wait time for lab sample results is minimized. This sensor paves the way for real-time release testing.

Features of the online PAT sensor:

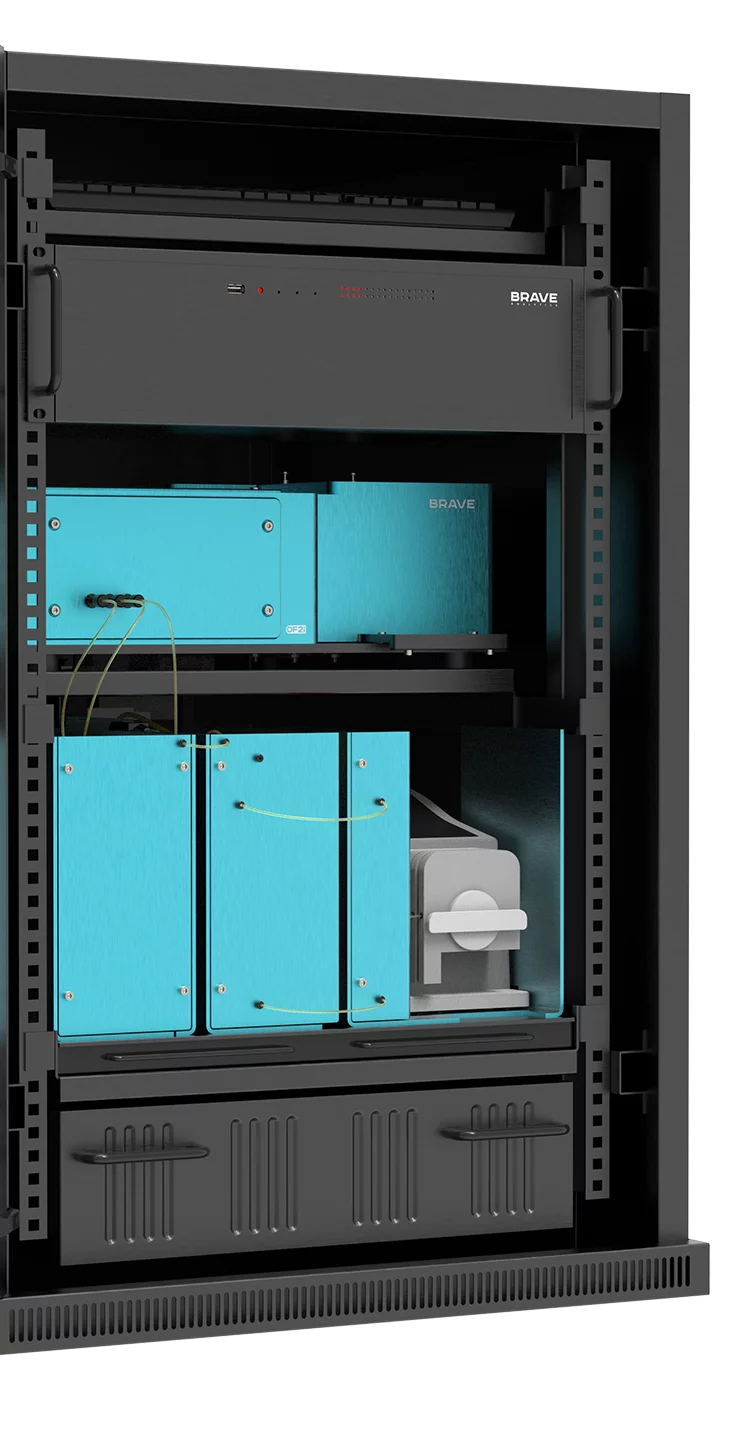

- Direct and easy integration to your production plant as an online PAT sensor

- Seamless measurement data in real-time 24/7

- Reliable and representative data with single-particle sensitivity

- Detection of large-particle tails, aggregates and anomalies

- Precise measurement of particle size, particle size distribution and particle concentration

- Basis for Real-Time Release Testing

- Important insights for predictive maintenance of your production plant

- Perfect documentation of measurement results

This is how BRAVE B-Continuous revolutionizes your production as an online PAT sensor

As BRAVE B-Continuous integrates easily into your production plant as a fully automated PAT sensor, enabling continuous, real-time monitoring. This way you obtain exact measurement data on particle size, number-based particle size distribution, and particle concentration without the need to rely on sample analysis from the laboratory. With the continuous measurement data from BRAVE B-Continuous, you can optimize and adapt your production process.

With BRAVE B-Continuous, online PAT sensor:

- You can reduce rejects as you now have total control of the particle sizes and are able to continuously monitor and adjust them.

- You don’t need to wait for lab test results and can optimize your processes in real-time. Measurement data is visible on your network in a matter of seconds.

- You obtain a better understanding of your production processes, as you constantly collect precious data for process optimization.

- You are able to monitor the health of your production plant and carry out maintenance in good time.

- You ensure the quality of your final product, as anomalies, aggregates and oversized particles will be identified.

- You can integrate checks on the filtration and dilution systems

- You establish a basis for RTRT (Real-Time Release Testing).

- You can focus entirely on your other tasks, confident that your production is running smoothly and the quality of your product remains assured.

Monitor and control your production processes

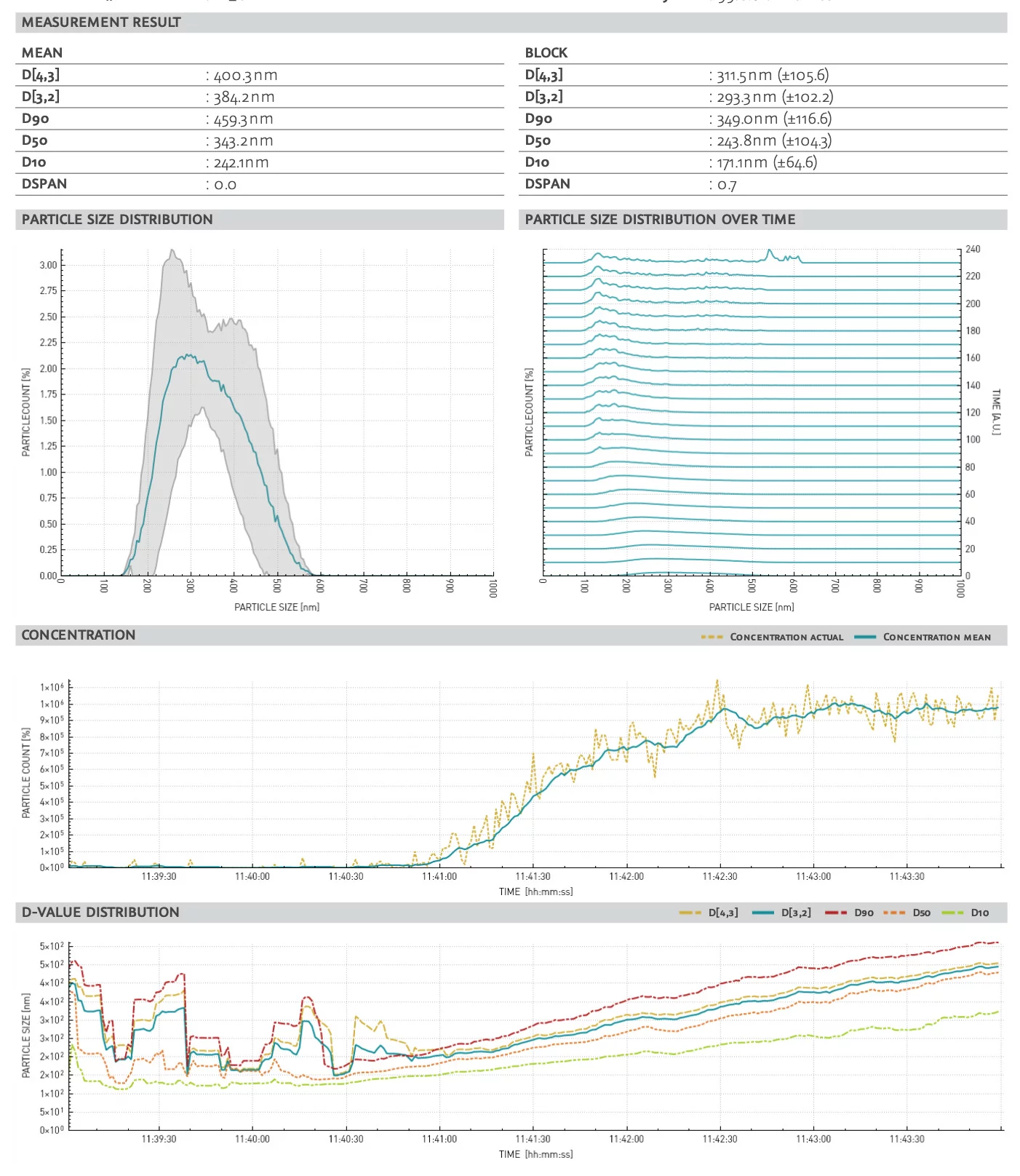

The monitoring and control of production processes reach new heights with BRAVE B-Continuous. It offers single-particle sensitivity, complete sizing histograms, and even detects large-particle counts. This minimizes the need for interim lab testing and reducing the risk of out-of-spec production.

BRAVE B-Continuous in action

Increase production efficiency with BRAVE B-Continuous

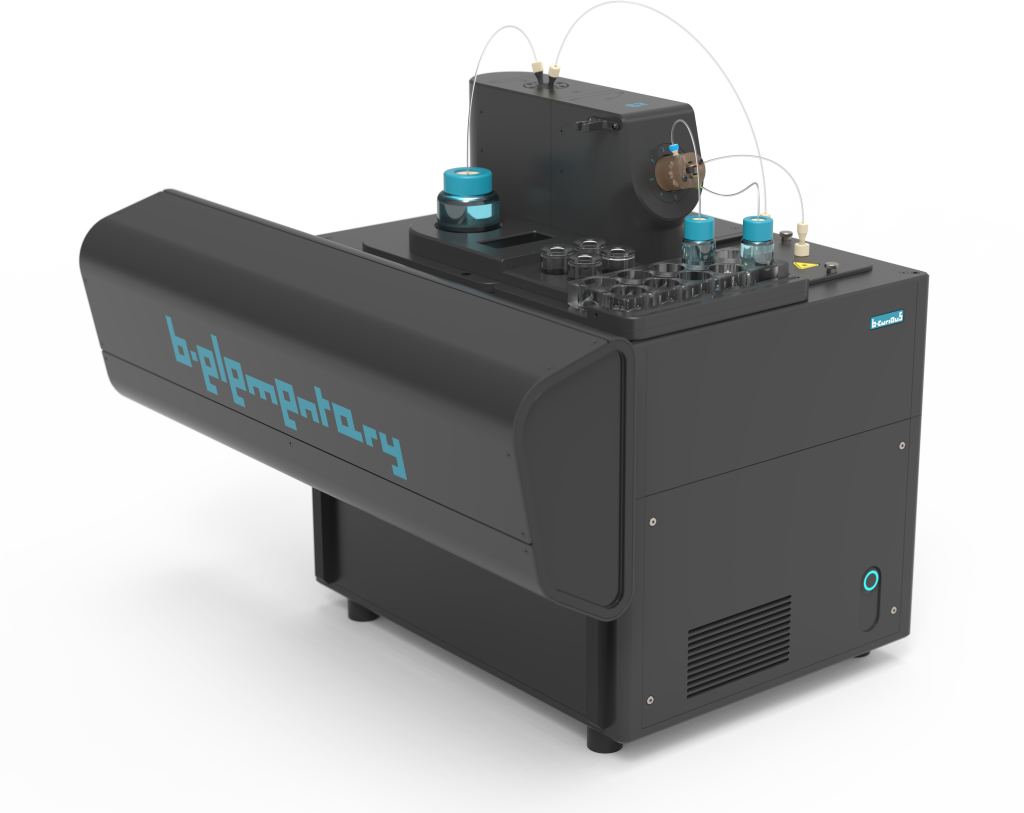

All of these benefits are possible because OF2i ® BRAVE’s new, patented method for particle size measurement is not restricted by the limits set by Brownian motion. Instead, OF2i® uses optofluidic forces, transfering momentum to nanoparticles via laser. This allows an ultramicroscope to measure the intensity of scattering, particle movement, and the number of particles per transported volume. This results in significant advantages for online measurement of particle size, particle size distribution, and particle concentration, offering superior performance over conventional nanoparticle analysis methods.

- As OF2i® is not dependent on measuring Brownian motion it therefore delivers measurement results instantaneously

- OF2i® measures up to 3000 particles per minute continuously to deliver statistically relevant values

- OF2i® measures with single-particle sensitivity and delivers D-values and particle size distribution (PSD curves) based on actual measurements without averaging or extrapolation

- The OptoFluidic Force Induction method is capable of detecting large-diameter particles, low-particle counts, particle tails, anomalies and other outliers

H.A.N.S., the software for BRAVE B-Continuous

The software controls the PAT sensor and generates measurement reports. H.A.N.S. features intuitive workflows, user-friendly interfaces, and customizable device parameters for tailored application and method development.

H.A.N.S. protects, analyzes, and reports your data

- User control and measurement logs towards 21 CFR Part 11 compliance are already included

- Measuring protocol as a PDF (signed and tamper-proof for full data integrity)

- Secure data transfer with signature verification

H.A.N.S. provides more:

- Access to raw data in CSV format

- Additional features available via OTA (over the air) update

- Remote support and updates via your network