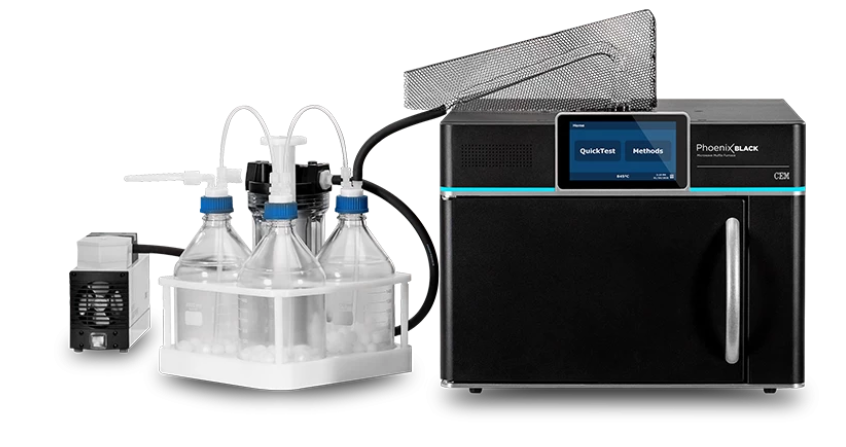

Le système Phoenix BLACK de cendres sulfatées offre une solution rapide pour l’incinération sulfatée, achevée en seulement 45 minutes Il suffit d'ajouter de l'H2SO42à4 échantillon, de placer le creuset dans le four, et le système chauffe automatiquement à 300°C pour le prélavage avant de passer à la température définie pour finaliser le processus.

La pompe à vide et le module de lavage intégrés éliminent et neutralisent en toute sécurité les vapeurs d'acide, améliorant ainsi la sécurité et simplifiant le nettoyage.

Il permet à l l'industrie pharmaceutique de réaliser Residue on Ignition (ROI) ou de cendres sulfatées pour évaluer les matières premières et les excipients. Il facilite également le contrôle de la qualité des produits finis tout en éliminant et neutralisant en toute sécurité les vapeurs d'acide sulfurique et nitrique.

Applications du système de cendres sulfatées :

Cendres sulfatées pour tout échantillon

Le Phoenix BLACK Sulfated Ash prend en charge l'incinération d'une large gamme d'échantillons,allant des concentrés, élastomères et glycérine, aux graisses, huiles lubrifiantes, produits pharmaceutiques, PVC, sucre, caoutchouc, et bien d'autres. Ce système est idéal pour l'incinération des déchets provenant des usines de traitement.

Caractéristiques du système de cendres sulfatées :

- Aucune pré-incinération nécessaire

- Élimine les projections et la formation de mousse

- Neutralise et filtre les vapeurs en toute sécurité

- Méthodes programmables et fonction de planification

- Conforme aux exigences pour les fours à moufle électriques et à micro-ondes

- Compatible avec tout type de creuset, y compris en platine et en fibre de quartz

Main-d’œuvre minimale requise

Le logiciel convivial facilite la création de méthodes personnalisées adaptées à des besoins spécifiques. Vous pouvez même programmer des heures de démarrage pour que le système soit prêt à votre arrivée. Pour plus de confort, associez-le à l’option station de travail, qui inclut une balance et une imprimante connectées, pour des résultats automatiques numériques et imprimés.

Le système supprime les procédures dépendantes de l’opérateur, comme l’utilisation de becs Bunsen, lampes chauffantes ou plaques chauffantes. Grâce aux méthodes multi-étapes contrôlées par ordinateur, chaque étape est gérée avec précision pour la documentation et la validation, permettant au personnel du laboratoire de se concentrer sur d’autres tâches.

Le Phoenix BLACK, associé à l’option d’incinération au sulfate, est équipé d’un système externe de lavage qui extrait et neutralise directement les gaz corrosifs provenant du four.

- La configuration est conforme aux normes ISO 14000 et à toutes les exigences de l'USP 281 (ROI) et de l'USP 733 (LOI).

- L'option d'incinération au sulfate peut être déconnectée et réajustée en moins de cinq minutes sans l'aide d'outils.

- La sortie de données USB fournit les détails de la méthode de conformité CFR21 part 11 et la date d'achèvement.