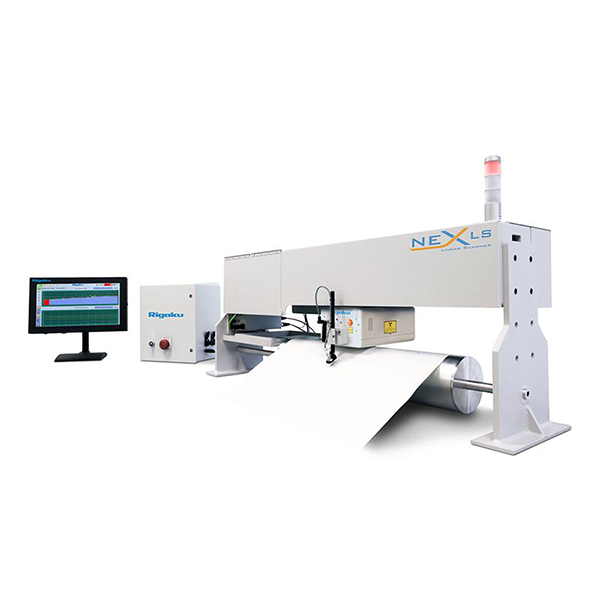

Analyseur de soufre en ligne

Le NEX XT offre des mesures en ligne et en temps réel par transmission de rayons X (XRT) du soufre, avec des concentrations allant de 0.04 à 6wt%, dans divers flux pétroliers (pétrole brut, fioul lourd et autres hydrocarbures très visqueux), quel que soit le type de flux.

Le NEX XT répond aux exigences variées de l’industrie.

C’est un analyseur compact, polyvalent et robuste de transmission/absorption de rayons X, spécialement conçu pour l’analyse totale du soufre dans les raffineries, les oléoducs, les processus de mélange et autres installations de stockage.

Applications du NEX XT :

Le NEX XT fournit des mesures en ligne et en temps réel par transmission de rayons X (XRT) du soufre, allant de 400 parties par million (ppm) à 6 % en poids, sur divers flux pétroliers. Il représente la nouvelle génération de solutions de processus pour la mesure du soufre dans le pétrole brut, le fioul marin, les huiles combustibles et d’autres hydrocarbures très visqueux.

- Mélange et suivi du pétrole brut et des matières premières de raffinage

- Mélange et suivi des carburants marins pour conformité aux réglementations OMI MARPOL .

- Contrôle qualité du pétrole brut dans les installations de collecte et de stockage éloignées

- Suivi des huiles de gaz à vide à haute température

Plus rapide et plus sensible

Grâce à du matériel spécialement développé et à des technologies logicielles innovantes propriétaires, le système NEX XT est plus rapide, plus sensible et beaucoup plus compact que les systèmes concurrents. Le NEX XT effectue des mesures continues et fiables du soufre à des pressions allant jusqu’à 100 bars et des températures jusqu’à 200°C, dans des configurations personnalisées. Le NEX XT fonctionne comme un analyseur autonome ou fournit un contrôle en boucle fermée en temps réel lorsqu’il est intégré dans un système de mélange ou d’automatisation à l’échelle industrielle.

Parmi les autres caractéristiques clés figurent une interface utilisateur simplifiée, une moindre dépendance aux étalons de calibration, une correction automatique de la densité, une protection par mot de passe, ainsi qu’une plateforme standardisée pour la communication des résultats de soufre vers un DCS (Distributed Control System).