Analyseur élémentaire EDXRF en temps réel des liquides

Grâce à une cellule d’écoulement avancée associée à la technologie EDXRF, l’analyseur de procédé Rigaku NEX OL fournit une analyse multi-éléments en ligne, de l’aluminium (Al) à l’uranium (U), dans les flux liquides. Le NEX OL supporte une large gamme d’applications de contrôle de procédé, des environnements industriels lourds aux solutions de mesure pour l’industrie des produits alimentaires.

Système configurable

Le système est configurable pour une utilisation en environnements classés ou non classés, propose une calibration simple et une opération de routine aisée, intègre des protocoles de communication standards et est équipé d’une interface utilisateur industrielle tactile intuitive.

Équipé de la technologie d'EDXRF

Le NEX OL est équipé de la technologie de fluorescence X par dispersion d’énergie (EDXRF), basée sur le NEX QC+ de paillasse haute résolution de Rigaku, et offre d’excellentes performances analytiques ainsi qu’une grande fiabilité.

Grâce à la combinaison de cette technologie éprouvée avec un tube à rayons X de 50 kV, un détecteur à dérive de silicium (SDD) et un ensemble optimisé de filtres pour le tube, le NEX OL est parfaitement adapté à une grande variété d’applications de contrôle de procédé.

Conception unique de cellule de flux sans outil

Pour l’analyse des flux liquides, le système associe la tête analytique à un ensemble unique de cellule de flux sans outil, comprenant une fenêtre pour rayons X. Cette fenêtre, généralement en film plastique, contient le flux liquide tout en restant transparente aux rayons X.

Épaisseur et composition du revêtement

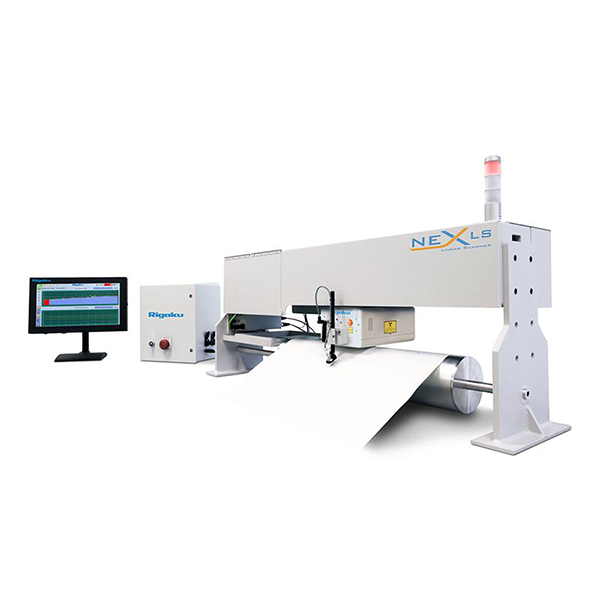

En plus d’analyser les flux liquides, le Rigaku NEX OL prend également en charge les applications sur bobines et surfaces continues. Il peut mesurer la composition multi-éléments et/ou l’épaisseur du revêtement. En général, la tête analytique est montée en position fixe au-dessus d’un rouleau, garantissant une distance constante entre la tête et la surface.