Analyse en ligne multi-éléments des revêtements par EDXRF

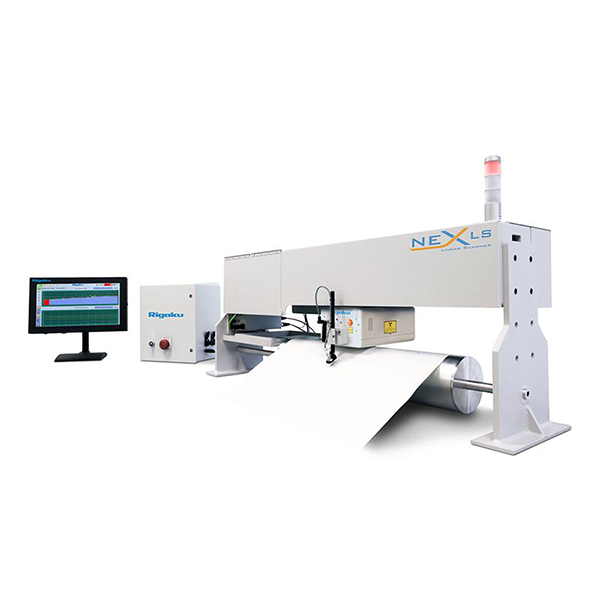

Le NEX LS est un spectromètre compact à fluorescence X par dispersion d’énergie (EDXRF) en ligne, idéal pour les analyses multi-éléments de revêtements. Le NEX LS prend en charge le contrôle qualité de routine dans les applications en bande (web) et en bobine (coil). Ce système fournit des données cruciales sur les propriétés des revêtements et la composition des produits.

La qualité du produit dépend d’une épaisseur de couche précise, d’un poids de revêtement correct et d’une composition élémentaire adéquate. Le NEX LS permet une surveillance continue de ces paramètres sans interruption de la production.

Principe de fonctionnement

Le NEX LS est un système de mesure en ligne par balayage intégrant la technologie EDXRF. Pour garantir des performances analytiques supérieures et une grande fiabilité, la tête de mesure EDXRF du NEX LS est basée sur la série éprouvée Rigaku NEX EDXRF de paillasse. Le NEX LS fournit une analyse élémentaire en temps réel des éléments allant de l’aluminium (Al) à l’uranium (U). Cela en fait un outil essentiel pour les processus de production roll-to-roll.

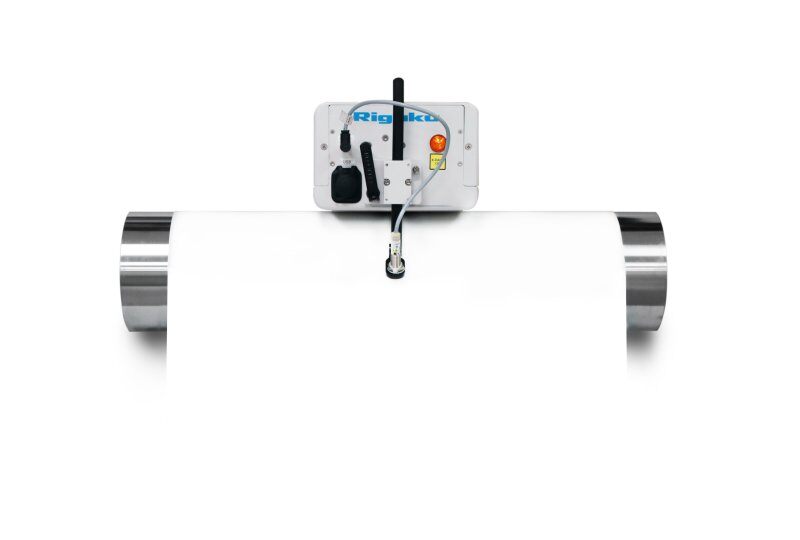

La tête d’analyse effectue un balayage linéaire sur un ruban ou une bobine en mouvement, transmettant les données à une unité de contrôle et à un ordinateur industriel à écran tactile. Les résultats sont affichés en temps réel sous forme de profils graphiques dans le sens transverse et longitudinal. Il est possible de choisir entre un mode balayage complet ou des positions d’analyse spécifiques. Outre la composition élémentaire, le système peut également mesurer le poids du revêtement ou son épaisseur. L’installation garantit une distance constante entre la tête de mesure et la surface.

Fluorescence X dispersive en énergie (EDXRF)

Pour garantir des performances analytiques supérieures et une fiabilité optimale, la tête de mesure EDXRF du NEX LS est basée sur les instruments de bureau haute résolution éprouvés de la série Rigaku NEX. Grâce à cette technologie éprouvée, le Rigaku NEX LS fournit des analyses multi-éléments rapides et non destructives. Il mesure le poids de couche, l’épaisseur et la composition des revêtements pour des éléments allant de l’aluminium (₁₃Al) à l’uranium (₉₂U).

Épaisseur et composition du revêtement

Le Rigaku NEX LS est idéal pour les applications sur bobines et surfaces continues, offrant une analyse multi-éléments de la composition, du poids de couche ou de l’épaisseur du revêtement. La tête de mesure est montée sur une poutre rigide et utilise un mécanisme de déplacement linéaire au-dessus d’un rouleau, garantissant une distance constante entre la tête et la surface.

Il mesure directement la composition élémentaire d’un revêtement lorsque cela est nécessaire. Le système peut également mesurer directement le poids de couche (ou l’épaisseur du revêtement), la fréquence de comptage d’un élément étant proportionnelle à son épaisseur. Alternativement, il peut mesurer indirectement en évaluant l’atténuation d’un élément du substrat, la fréquence de comptage étant alors inversement proportionnelle à l’épaisseur.

Analyse des revêtements à base de silicone

Le NEX LS est un système de mesure en ligne par balayage intégrant la technologie EDXRF. Pour garantir des performances analytiques supérieures et une grande fiabilité, la tête de mesure EDXRF du NEX LS est basée sur la série éprouvée Rigaku NEX EDXRF de paillasse. Le NEX LS fournit une analyse élémentaire en temps réel des éléments allant de l’aluminium (Al) à l’uranium (U). Cela en fait un outil essentiel pour les processus de production roll-to-roll.

La tête d’analyse effectue un balayage linéaire sur un ruban ou une bobine en mouvement, transmettant les données à une unité de contrôle et à un ordinateur industriel à écran tactile. Les résultats sont affichés en temps réel sous forme de profils graphiques dans le sens transverse et longitudinal. Il est possible de choisir entre un mode balayage complet ou des positions d’analyse spécifiques. Outre la composition élémentaire, le système peut également mesurer le poids du revêtement ou son épaisseur. L’installation garantit une distance constante entre la tête de mesure et la surface.

L'analyseur de revêtement multi-éléments est excellent pour :

- Les revêtements à base de silicone sur plastique ou papier, plastiques thermoformés sous vide…

- Les films barrières contre l’humidité et l’air

- Les revêtements de conversion

- Les plastiques métallisés

- Revêtements de conversion

- Chargement des piles à combustible

- Les revêtements de surface sur bobines métalliques

- Revêtements de surface sur bobine de métal